OEM Aluminum Die Casting Parts for New Energy & Automotive Applications | Shengxu Parts

Product Overview

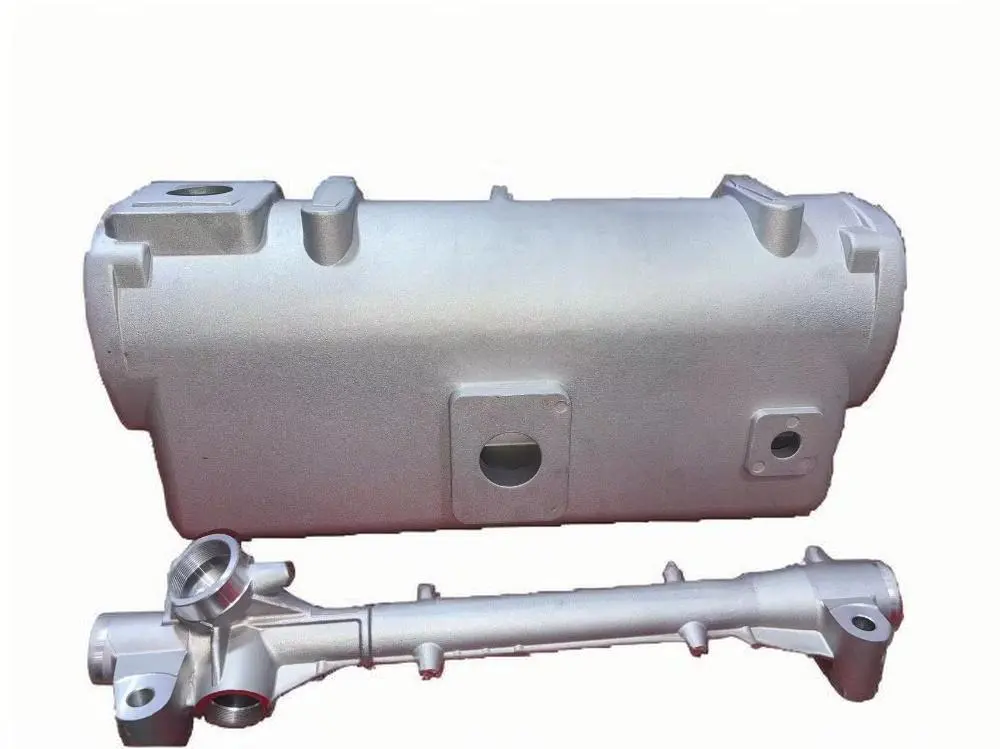

Precision Aluminum Die Casting for the Future of Mobility

Welcome to Ningbo Shengxu, your expert partner for high-performance custom aluminum die casting parts engineered for the demanding needs of the new energy vehicle (NEV) and modern automotive industries.

In an era where lightweighting is critical for efficiency and range, our OEM components are precision-engineered to meet the highest standards of strength, thermal management, and durability. We leverage advanced aluminum die casting and CNC machining processes to deliver complex, net-shape parts that integrate seamlessly into your electric vehicle powertrains, battery systems, and chassis assemblies.

Partner with us to reduce assembly complexity, enhance performance, and accelerate your time-to-market with reliable, mass-production-ready solutions.

Key Features & Advantages

Engineered for Superior Performance & Efficiency

1. Optimal Lightweighting without Compromise

Benefit: Significantly reduces vehicle weight to extend EV battery range and improve overall energy efficiency.

How: We use high-grade alloys like A356 and ADC12, known for their excellent strength-to-weight ratio.

2. Complex, High-Integrity Geometries

Benefit: Achieve sophisticated designs with thin walls and integrated features, reducing the number of parts and potential failure points.

How: Our high-pressure die casting (HPDC) process allows for exceptional detail and dimensional stability in a single component.

3. Enhanced Thermal Management & Durability

Benefit: Ideal for critical thermal management applications. Aluminum's innate heat dissipation properties protect sensitive electronics and powertrain components.

How: Parts can be finished with anodizing, powder coating, or other treatments for superior corrosion and wear resistance.

4. End-to-End Customization & Quality Assurance

Benefit: A seamless journey from design to delivery, ensuring your specs are met precisely and consistently.

How: Our full-service approach includes mold design, prototyping, and full-scale production, backed by a strict IQC/IPQC/FQC system and advanced measuring equipment (CMM, X-ray).

Application Scenarios

Critical Components for Advanced Automotive Systems

● EV Battery System: Battery pack enclosures, cooling plate covers, busbar supports. (Demanding: Sealability, EMI shielding, crashworthiness).

● Electric Powertrain: Motor housings, inverter cases, reducer housings. (Demanding: Heat dissipation, EMI shielding, structural integrity).

● Thermal Management: Heat sink plates, housing for cooling systems, compressor brackets.

● Chassis & Body: Lightweight structural brackets, sensor mounts, steering components. (Demanding: High strength, fatigue resistance).

Why Choose NBSX as Your Die Casting Partner?

● Deep Industry Expertise: We focus on the automotive sector, understanding its strict tolerances, volume requirements, and quality standards.

● Vertical Integration: Our capabilities in aluminum casting, stamping, and CNC machining mean you get a consolidated, reliable supply chain.

● Proven Global Supplier: We have extensive experience shipping and supporting international clients with reliable logistics.

● Commitment to Innovation: We continuously invest in technology and process improvement to offer you the most competitive and advanced solutions.

Call to Action

Ready to Optimize Your Automotive Components?

Submit your drawings or specifications today for a free, no-obligation project review and quotation. Our engineering team is ready to collaborate on your next project.

Contact Us Now to Get Started!