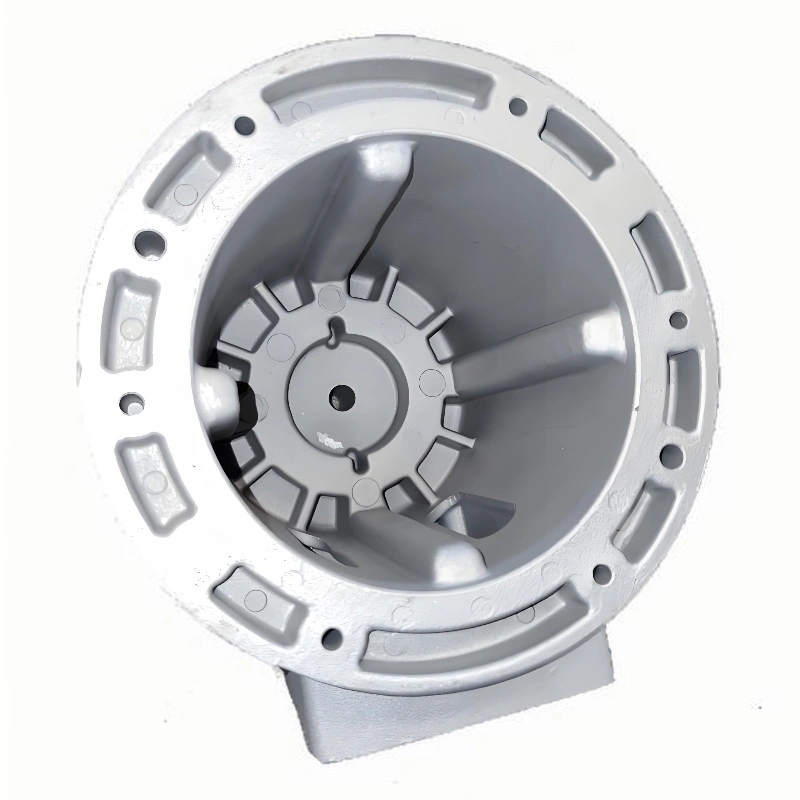

Ningbo Shengxu OEM Customized Aluminium Alloy ADC12 A356 A380 Material Accessory Part

Ningbo Shengxu is a leading China-based manufacturer specializing in high-quality custom aluminum die casting parts for global clients. We provide comprehensive OEM/ODM manufacturing services, producing complex, high-tolerance components using premium ADC12, A356, and A380 aluminum alloys for industries like automotive, telecommunications, and consumer electronics.

Key Features & Advantages

1. High-Performance Aluminum Alloys for Demanding Applications

We select the optimal material for your project's specific requirements, ensuring performance, cost-effectiveness, and durability.

ADC12 Aluminum Die Casting (Equivalent to A383):

● Best For: Excellent fluidity, good corrosion resistance, and pressure tightness.

● Ideal Use: Thin-walled, complex shapes like electronic housings, consumer appliance parts, and automotive components. Offers a superb surface finish for plating or painting.

A356 Aluminum for Heat Treatment (T6 Temper):

● Best For: Superior strength-to-weight ratio, high elongation, and exceptional impact toughness after T6 heat treatment.

● Ideal Use: High-integrity structural components like automotive wheels, aerospace brackets, and robotic arms where safety and strength are critical.

A380 Aluminum Die Casting:

● Best For: The most common die-casting alloy, offering the best combination of strength, corrosion resistance, and castability.

● Ideal Use: Engine blocks, transmission housings, power tool bodies, and other applications requiring a robust, reliable, and cost-efficient part.

2. Advanced Manufacturing & Strict Quality Control

● High-Pressure Die Casting (HPDC): Our machines produce parts with fine-grained microstructure and excellent dimensional stability.

● Precision Mold Making: In-house mold design and fabrication ensure high accuracy, repeatability, and long tooling life.

● Comprehensive QC: We implement a full quality management system, including:

◌ Material Certification

◌ In-process Dimensional Checks

◌ Spectrometer Analysis

◌ X-ray Inspection for internal porosity

3. Superior Product Performance

● Lightweight & Strong: Achieve significant weight reduction without compromising structural integrity.

● Excellent Thermal Conductivity: Perfect for heat sinks and LED lighting housings.

● High Corrosion Resistance: Ensures long-term reliability in harsh environments.

● Ready for Machining: Die-cast blanks are ideal for secondary CNC machining to achieve tight tolerances.

4. Extensive Surface Finishing Options

Enhance appearance, functionality, and durability with our wide range of surface treatments:

● Painting & Powder Coating

● Anodizing (Clear & Color)

● Electroplating (Nickel, Chrome)

● Polishing & Sandblasting

5. End-to-End OEM/ODM Customized Services

● Design for Manufacturability (DFM) Support: Our engineers optimize your design for the die casting process to reduce cost and improve quality.

● Rapid Prototyping: Get functional samples quickly to validate your design before mass production.

● From Low-Volume to High-Volume Production: Scalable manufacturing capacity to meet your demand, ensuring on-time delivery.

Industries We Serve

● Automotive Parts: Engine brackets, transmission cases, sensor housings.

● Telecommunications: 5G base station housings, antenna components, router chassis.

● Electronics & Appliances: Heat sinks, laptop frames, washing machine components.

● Power Tools: Durable housings and internal structures.

● Industrial Machinery: Pump housings, motor end plates, hydraulic parts.

Why Choose Ningbo Shengxu as Your Die Casting Partner?

● Material Expertise: In-depth knowledge of ADC12, A356, and A380 alloys.

● Quality Commitment: ISO 9001 certified processes with rigorous inspection.

● Cost-Effective Manufacturing: Competitive pricing without compromising on quality.

● Project Partnership: We work as an extension of your team, from concept to delivery.

Ready to Start Your Project? Contact Us Today for a Free Design Consultation & Competitive Quote!