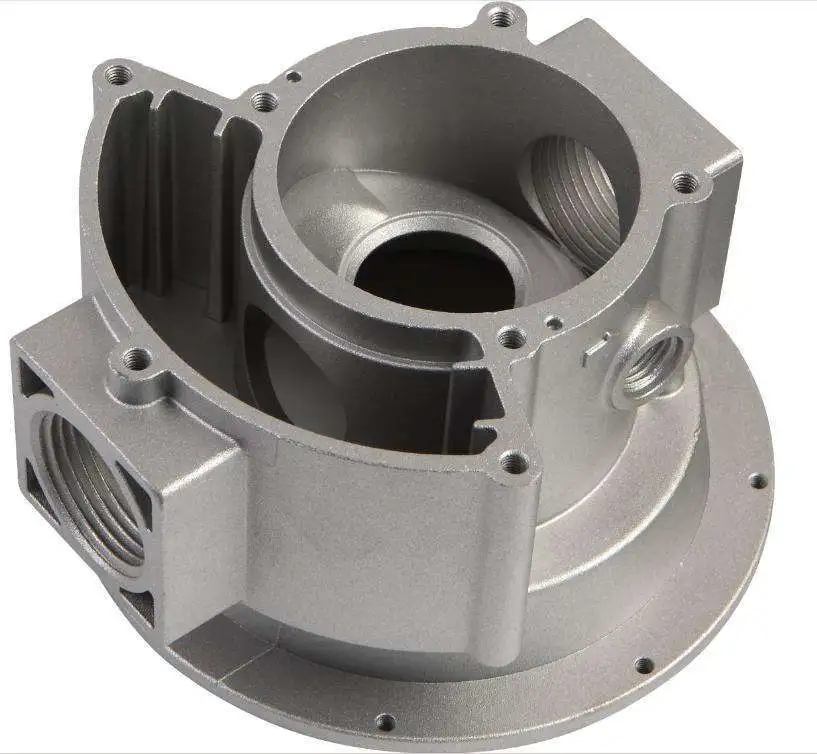

OEM customized aluminum alloy die-castings, high-quality precision metal components

Precision Aluminum Die Casting Manufacturer & Supplier

Ningbo Shengxu International Trade Co., Ltd. is a leading China-based manufacturer specializing in high-pressure aluminum die casting and the production of high-quality precision metal components. We deliver end-to-end OEM/ODM solutions, from mold design and prototyping to full-scale production and secondary operations.

Our expertise extends across multiple casting processes, including aluminum die casting, zinc die casting, and copper casting, complemented by our aluminum stamping and CNC machining capabilities. We serve a global clientele by producing durable, complex, and dimensionally accurate parts that meet rigorous international standards.

Why Choose Our Aluminum Die Casting Services?

1. Advanced High-Pressure Die Casting

● Utilize state-of-the-art cold and hot chamber die casting machines to produce parts with excellent dimensional stability, fine surface finish, and high density.

2. Strict Quality Control & Precision

● From raw material inspection to final shipment, our process is monitored with CMM, X-ray, and spectrometers. We guarantee consistent quality and tight tolerances for every production run.

3. Comprehensive Material Selection

● Primary Material: Aluminum Alloy (ADC12, A380, etc.) - for excellent strength-to-weight ratio and corrosion resistance.

● Alternative Materials: Zinc Alloy for enhanced hardness and plasticity; Copper Alloy for superior conductivity.

4. Integrated Secondary Services

● We provide a complete post-processing service package, including CNC machining (turning, milling), surface treatment (painting, powder coating, plating), and anodizing, offering a true one-stop manufacturing solution.

5. Expert OEM/ODM Support

● Our engineering team offers Design for Manufacturability (DFM) analysis to optimize your part design, reduce costs, and improve performance before mass production begins.

Industries We Serve

Our custom die cast components are critical to the performance of products across diverse industries:

1. Automotive Parts

● Components: Engine brackets, transmission housings, EV motor enclosures, brake system parts.

● Value: Lightweighting, heat dissipation, and structural integrity for automotive applications.

2. Hydraulic & Pneumatic Systems

● Components: Valve bodies, pump housings, manifolds.

● Value: High-pressure integrity, leak-proof performance, and complex internal channel formation.

3. Industrial & Engineering Machinery

● Components: Gearbox covers, machinery housings, robotic actuator parts.

● Value: Durability, wear resistance, and the ability to withstand harsh operating environments.

4. Telecommunications & Electronics

● Components: Heat sinks, device enclosures, RF shielding boxes.

● Value: EMI shielding, efficient thermal management, and aesthetic finishes.